The screen printing process starts with the making of the screens. These are made by putting a chemical emulsion onto a mesh surface. Vector artwork is ideally taken from Adobe Illustrator and printed out onto a film type paper or vellum. The screen is then exposed on a light table with the artwork under it. The light solidifies the chemicals around the design, and where the light failed to pass through, the chemical breaks down. The screen is then rinsed out and what is left is the area where the light hit.

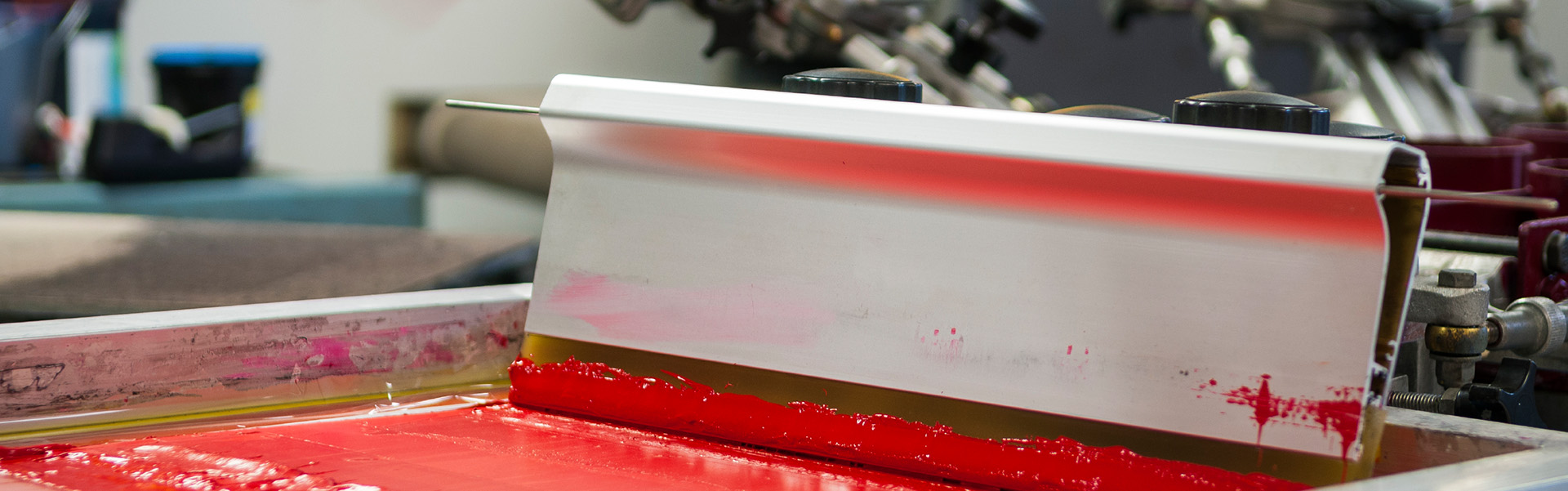

The product is placed onto a platen and each screen swings around over the top of the product. The screen is then brought down and placed on top of the product. A squeegee is then pulled over that screen’s ink colour which pushes the ink onto the product fabric. That screen is then lifted, carefully off of the product .The platen with the product is then moved under a flash unit where it dries. Upon curing, the shirt platen is brought back and the next colour screen is swung over the top of it.

When screen printing, one colour at a time is applied and therefore the cost will increase with each additional colour applied. Likewise a separate screen is required for each colour, and hence, screen charges may be uneconomical if only a small quantity of clothing is required.